Customer states unit exhibited a burning smell and sparks coming from fan area back right side of unit halfway through a performance and asked me to take a look to see what the issue was.

First needed to repeat customer concern before doing anything in case act of opening up case changes something. Powered up on DBT and variac, could hear faint start-up pulsing of class D switching components but nothing obviously shorted so applied full power. Around the timing of a startup pulse, a loud crack and spark could be seen, so immediately powered off.

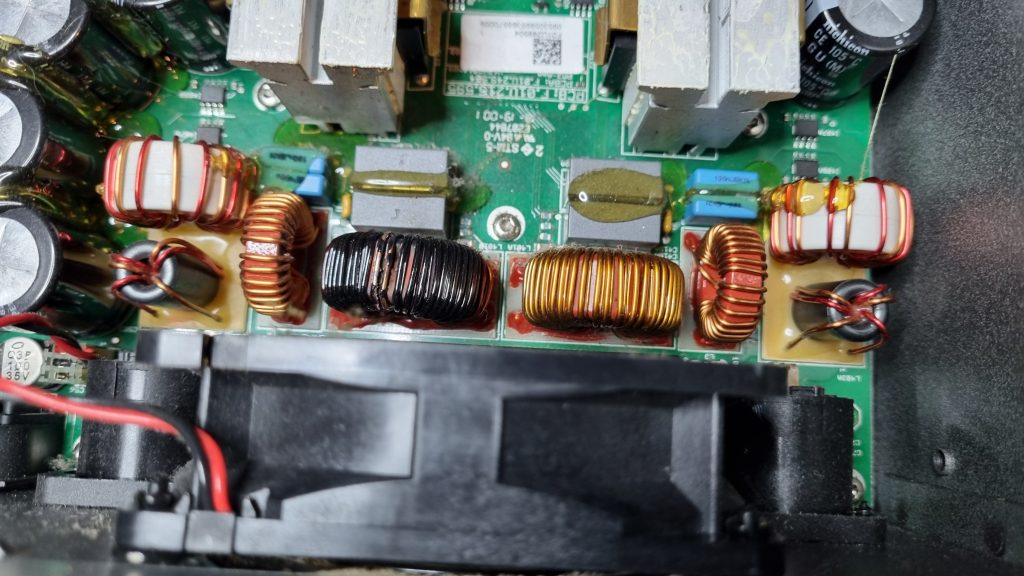

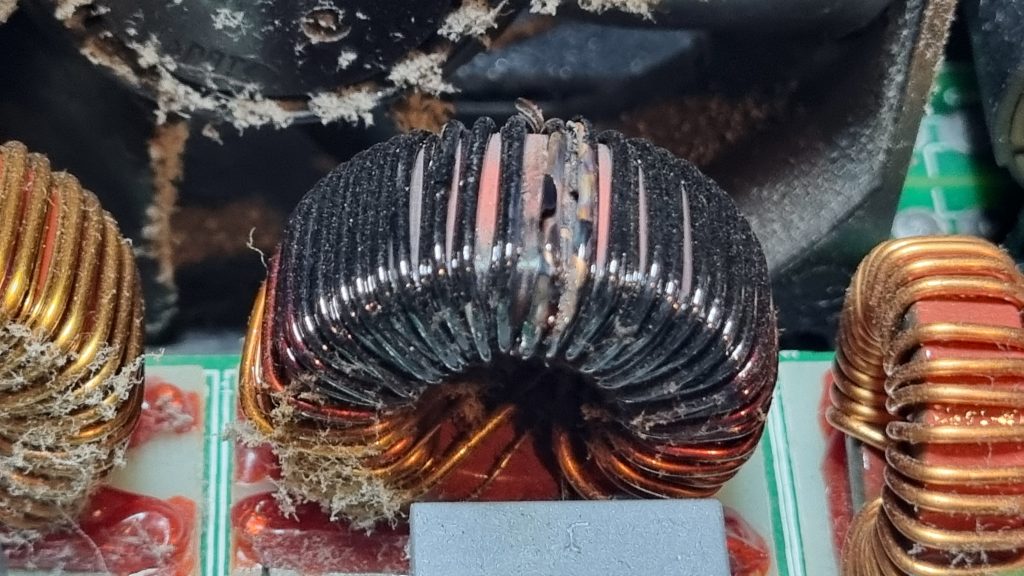

Opened up case and inside shielding cover plate – after about 66 screws later – to see the RH channel filter coil rather charred and looking very unhappy:

Clearly overheated, looks like shorting to ground via thinner sense coil wire, and possibly a breakdown in insulation over time and/or a microfracture during original manufacture. Probably the arcing was main cause of the overheating damage seen, although it’s also possible that thermal runaway occurred leading to the failure. Either way, needs replacement. A little bit of dust build-up too which was cleared up, but not sufficient to have been a causal factor.

The coils on their carriers were removed from main board and Dynacord (Bosch/Keenfinity) were contacted to enquire about spares as appears to be a custom wound part. In the meantime ordered some replacement ferrite toroids and enamelled copper wire as not got any 1mm and 0.3mm in stock, with the intention to rewind by hand.

Dynacord eventually responded that only the entire board can be supplied – at a cost pretty much exceeding the value of the unit, which is just beyond shameful, wasteful and frankly quite ridiculous for what is essentially a bit of broken wire.

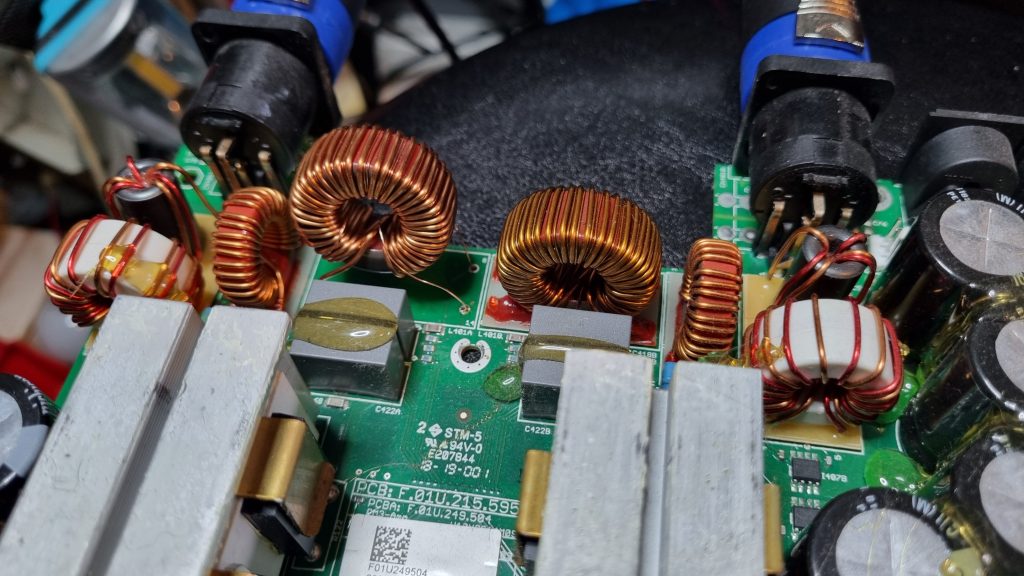

Wired up a new coil from scratch, 20uH for both windings (burnt out toroid former on left, new middle and existing LH coil on the right):

Installed into LH good channel side to test (and prove nothing else faulty with the RH side that burnt up) :

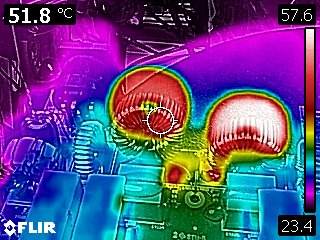

Noticed the new coil was a bit cooler on thermal camera than the old one in the RH channel after a couple of minutes at idle (and both sides sounded ok passing audio):

So just to rule out any other issue with the Right channel, swapped them over so the old coil was back in the LH channel where it was, and the increased temperature difference moved with the old coil. So possibly a bit more ac core loss with the original than the newly wound unit (no distortion or anything noticeable on the outputs driving 4 ohm 1000W dummy loads):

All looked (and sounded) good, so fitted new wound coil back to the original carrier PCB, with a little coating of high temperature MG 4226 clear insulation varnish and securing to PCB with MG4228A red varnish (good up to 180C as these coils run hot!), oven cured for 2 hours.

Fitted coil to main PCB and tested:

Cleaned up both fan’s blades as were fairly dusty, applying some 303 Aerospace protectant to hopefully reduce future buildup:

Soak tested the unit for a couple of hours or so and all good.

I did notice that the fans only run when the Class D amp is actively working, otherwise only come on briefly from time to time, if this unit is not connected to passive speakers and instead used with active speakers from the Master outs, then it’s likely the coils may not get the expected amount of cooling – perhaps a modification to have the fans run continuously at low speed wouldn’t be a bad idea, however the lack of schematics/service information from Dynacord is very disappointing.

#RightToRepair